Global technology supplier Bosch Australia Manufacturing Solutions (BAMS) has developed a way to enable rapid and automated assembly of heliostats (mirrors used to focus sunlight) in collaboration with RayGen for the rollout of their concentrated solar power plants.

The process is to be deployed on site at RayGen’s first utility scale, Carwarp 4 MW solar and 2.8 MW / 50 MWh storage project in Victoria, after rigorous in field testing, and involves the assembly of heliostats on a highly automated BAMS-designed production line.

The automation capabilities will make assembly a faster and lower cost process, with the aim to assemble a heliostat every three minutes.

Each heliostat measures approximately 4×5 metres and are comprised of eight individual mirror panels that must be assembled to tight tolerances to maximise the energy produced by the solar technology.

RayGen Chief Executive Officer Richard Payne said automating the company’s assembly processes with the industry experts is essential for RayGen’s mission to scale technology to a global customer base.

“We’re delighted to partner with Bosch Australia Manufacturing Solutions, and we look forward to working more closely with the Bosch team,” Payne said.

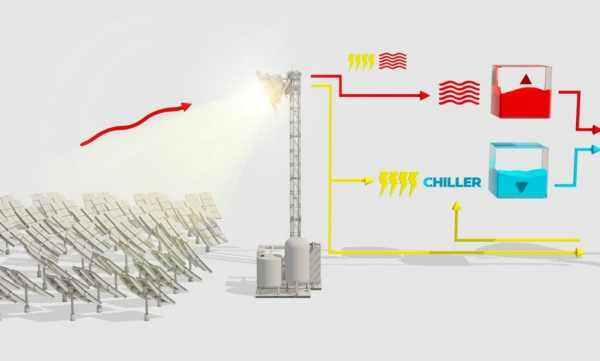

RayGen combines concentrated solar technology with integrated heat collection used to drive a turbine to enable on-demand, dispatchable renewable energy, day or night.

Image: Australian Renewable Energy Agency

The project’s electro-thermal storage system consists of an organic Rankine cycle (ORC) turbine, industrial chillers and two insulated water-based thermal storage pits or reservoirs, each roughly the size of four Olympic size swimming pools.

One of the reservoirs is kept at a temperature of 90 degrees and the other at close to 0 degrees, and the temperature difference is used to generate dispatchable electricity using ORC turbines.

The Carwarp demonstration project provides reliable, on-demand power to the West Murry distribution network in northwest Victoria, offering improved grid security and reliability with synchronous generation.

Popular content

RayGen plans to build a utility-scale power plant with 200 MW solar capacity and 115 MW / 1.2 GWh of storage that would be enough, on average, to power around 45,000 homes for more than 10 hours.

Image: Bosch

The project has an offtake agreement with AGL and was supported by a $15 million (USD 9.9 million) Australian Renewable Energy Agency (ARENA) grant toward the total cost of $30 million.

ARENA Chief Executive Officer Darren Miller said at the time of announcing the grant, RayGen’s innovative technology provides an exciting opportunity to address Australia’s emerging longer duration storage needs.

“RayGen’s technology has many benefits for the energy market as we continue the energy system transformation being driven by renewables. We are particularly interested in the potential for RayGen’s technology to deliver firmed renewable energy at a very competitive cost,” Miller said.

ARENA previously supported RayGen with a total of $8.67 million in funding to develop its Solar Ultra technology and build a 1 MW Solar Ultra pilot project in Newbridge, Victoria. The pilot project has been powering a local mushroom farm.

The latest collaboration with BAMS announcement follows a $51 million capital raise by RayGen earlier in 2024, when global oilfield services giant SLB invested $31 million, and investment fund manager Breakthrough Victoria, $20 million, to help RayGen expand its solar cell manufacturing capacity at a new facility in Melbourne.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.